Exemplary service. An embodiment of values.

At Southern Garage Doors, we don’t install stock torsion springs. Each spring is custom-cut and tailored to your specific door’s weight and hardware — measured, balanced, and wound on-site for precise performance.

Years ago, this was the standard practice in our industry. Every technician carried the tools and know-how to measure, weigh, and cut springs for each door right there at the home. Over time, many companies moved away from it — replacing craftsmanship with convenience and installing pre-boxed, one-size-fits-all springs to save time.

We’ve chosen to keep doing it the old-fashioned way — because it’s still the best way. By cutting and fitting springs on-site, we ensure your door is perfectly balanced, operates quietly, and lasts longer. It takes more care, but it’s the kind of work we’d want done on our own homes — and that’s what matters most.

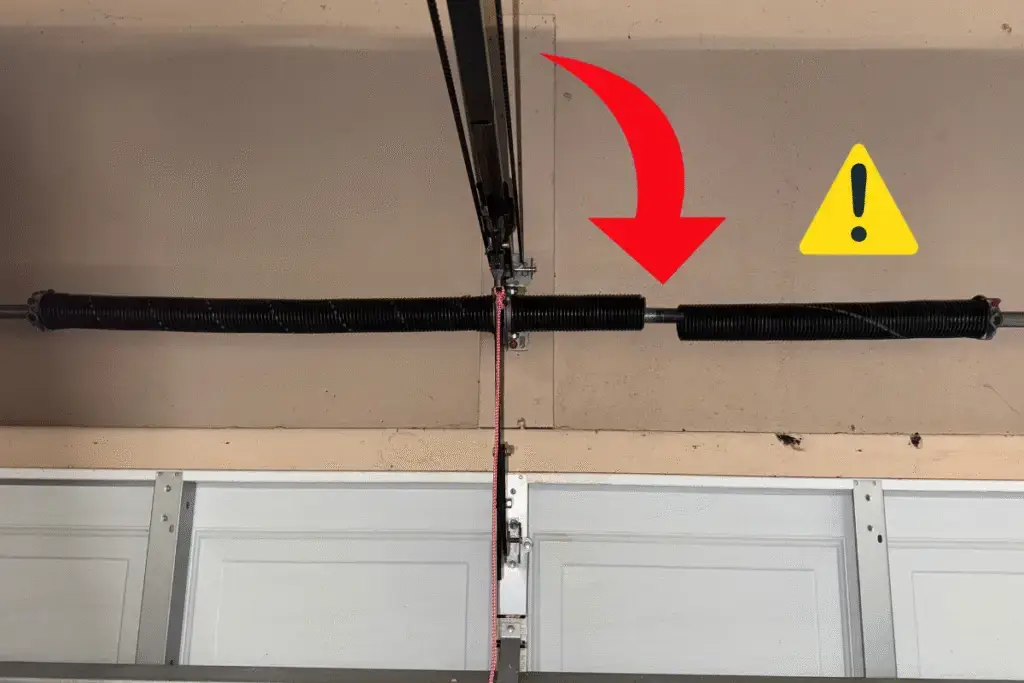

A broken torsion spring is one of the most common — and most disruptive — garage door failures. You may hear a sharp snap or bang, or find the door suddenly too heavy to lift. Springs are what counterbalance the full weight of your door — often more than 200 pounds.

Standard factory springs are typically rated for about 10,000 cycles (one open + close = one cycle). For many families, that’s five to seven years of daily use before fatigue sets in.

When a spring fails:

The door becomes unsafe to lift

The opener strains or cannot move the door

Additional components may wear prematurely

The system becomes unsafe to operate

This is not a repair to force or “get by” with. It requires careful measurement, the right tools, and precision.

At Southern Garage Doors, we see a broken spring as more than a mechanical failure — it’s an opportunity to restore balance, safety, and confidence in how your door operates.

We take time to look at the whole system — not just the broken spring — so the repair fits the door, not the other way around.

With the tension released, we slide a scale under the bottom panel to find its true weight — not an estimate or a guess. This measurement prevents over- or under-sized springs from being installed and ensures the entire system is balanced before anything new is added. Knowing the exact weight protects your opener, keeps the door neutral, and sets the foundation for a safe, long-lasting repair.

Once the door’s weight and height are confirmed, we select the precise wire size and length from the coils we carry on the truck. Each spring is measured, cut, and fitted on-site — the way craftsmen used to do it before the industry shifted to one-size-fits-all replacements. We carry multiple wire sizes for accurate matching, fit each spring specifically to your door, and check the ends before installation. A properly matched spring lasts longer, runs quieter, and reduces unnecessary strain on your opener.

The new springs are mounted on the torsion bar, the cables are set, and the coils are wound carefully by hand — roughly one full turn per foot of door height, then adjusted until the balance feels exactly right. We use proper winding bars only, never drills, and we tighten the cable drums evenly on both sides. Finally, we lift the door by hand to confirm that it sits in neutral balance. Correct tension ensures the door lifts smoothly and evenly, whether operated manually or by the opener.

We reconnect the opener and run the door through several full cycles, checking that the travel limits are correct, adjusting force settings as needed, and confirming the safety sensors respond properly. Lubrication is applied to the moving points so the door travels smoothly. This final calibration step makes sure the springs, door, and opener work together as a single, quiet, dependable system.

After testing and calibration, we walk you through the work so you know exactly what was done and how the door should feel. Once everything is clear, we collect payment and provide your documentation. Your warranty coverage begins at that point, giving you straightforward protection and closing the job with the same care shown throughout the repair.

Identify broken or fatigued springs

Inspect cables, drums, bearings, center plate

Evaluate gear ratios and height-to-turn requirements

Door weighed to determine exact lift requirement

Custom wire size selected

Springs cut and fitted onsite

Springs mounted and wound

Drums aligned and tightened

Door balance tested manually

Force settings tuned for new spring load

Travel limits tested

Safety beams confirmed

Smooth travel verified

Neutral balance confirmed

All moving points lubricated

With springs cut to your door’s exact weight, the door moves smoothly and evenly, without the grinding, jerking, or strain caused by mismatched stock springs.

Correct wire size, proper winding, and true balance reduce stress on the opener and hardware, giving the whole system a steadier, safer feel every time it moves.

We show you how a properly balanced door should lift and hold, explain the adjustments made, and make sure you know what to expect from a correctly fitted spring system.

Custom-cut springs matched to the door’s real weight — not pre-boxed substitutes — extend the lifespan of the system and prevent the uneven wear common with generic replacements.

Trustindex verifies that the original source of the review is Google. Fantastic company for garage door repair. The chain on our door motor broke in the evening last Wednesday and Matthew was able to get us up and running with a new motor by a little after lunch time the very next day. Setting up the appointment was super quick and easy and he was here right on time to take a look at the problem. He offered to try and fix the old opener, but it was 18 years old, so I was ready to get it replaced. Matthew explained all of the options between the different brands and model tiers, and didn't try to upsell me at all. He recommended a model with fewer bells and whistles, which was perfect for my needs. The work was quick (couple hours max) and everything looks and works great. And to top it all off, he helped to reset the buttons on both our car mirrors so that our vehicles and garage door were back to fully integrated. From contacting them at around 8 am to fully installed and operational by 1 pm. You can't do any better with any type of home repair service. Highly recommend Southern Garage Doors.Trustindex verifies that the original source of the review is Google. You can't ask for better service, quality, timeliness, or professionalism! Mathew takes a great of pride in the service and quality provided by Southern Garage Door. He is honest, incredibly competent, prompt, and professional. His work ethic is remarkable and I have no hesitation whatsoever in recommending Mathew ……. Southern Garage Doors is simply the BEST!

Owner's reply

Thank You!Trustindex verifies that the original source of the review is Google. Reviews are not my thing, but I would be remiss to let the fine work that Matt has done for me go without praise. I can't say enough how much I appreciate the prompt resolution and caring approach given to my broken garage door. Zero pressure sales, and should my situation have warranted spring replacement the price was less than half what I paid previously. If you live in Sarasota you owe it to yourself to contact Southern Garage Doors for help with anything you need related to your garage door. In my case there was no need to replace any parts and simply servicing what I already had was sufficient.Trustindex verifies that the original source of the review is Google. Responded immediately, easy scheduling, excellent, friendly, and professional service. Quick turnaround with fixing the problem. Thanks Matthew!Trustindex verifies that the original source of the review is Google. We highly recommend Southern Garage Doors to anyone looking to have their garage door system repaired & serviced and refer them as a very trustworthy company. Mathew performed an inspection including finding a couple of issues and performed meticulous adjustments! The cost of Mathews servicing we felt was more than reasonable!Trustindex verifies that the original source of the review is Google. I had my garage door serviced a couple weeks ago by a large, well known company. Service was fine but not a good fit for me with a delay, 4 hour arrival window, unclear pricing and too many package plans. Coincidentally, yesterday the large door spring broke! I read reviews and called Southern. They gave pricing over the phone and Matthew came this morning and custom cut a new spring to exactly fit. I understand few places offer this service and use precut. He also added screws to each side of the door, which he said were often left off on single doors, and replaced the light bulb. There were no extra charges for these and NO package plans. Thanks for fixing my “spring break!” 😊Trustindex verifies that the original source of the review is Google. From the time I called until my door was fixed was under 2 hours!Trustindex verifies that the original source of the review is Google. Matt was great. Best garage service I've ever received. How best? Matt repaired every little fault he found with either door but kept the total price at his original estimate which was reasonable and less than what I expected. Matt took the time to explain to me how to change access codes, other suppliers acted like it was difficult. And, I loved the formal repair summary that Matt left for me to review. Thanks and Peace Joe MurphyTrustindex verifies that the original source of the review is Google. Matthew came to replace our garage door spring and did an excellent job. He communicated clearly, was kind, and took the time to answer all of my questions. Thank you, Matthew!Trustindex verifies that the original source of the review is Google. these guys are great. called at 8:15 am for a door that got off track and bent when tailgate of SUV got caught in door not allowing door to open manually or with opener. Matt arrived by 10:30 am and door is fixed and working for a very reasonable price. thank you- very professional and personable.

If it’s been a year since your last tune-up, give us a call when it fits your day. No pressure — just a careful inspection, quiet adjustments, and clear communication from start to finish.

Over time, every cycle of your garage door — one full up and one full down — bends the spring just a little. Think of it like bending a paper clip back and forth: eventually it fatigues and snaps. The spring is doing the heavy lifting for your door and with each cycle the metal gets a little “tired.” At that point the spring has simply reached the end of its safe life. Replacing only the spring that broke doesn’t stop the same fatigue that exists in the other spring on the door.

A “cycle” refers to one complete opening and one closing of the garage door. Springs are rated by how many cycles they can perform before fatigue—typically around 10,000 cycles is the industry standard for residential torsion springs. So when you think about how often you use your door — twice a day, five times a day, or more — you can see how the number of cycles adds up and tells you when a spring is nearing the end of its life.

The commonly cited baseline is around 10,000 cycles for standard residential torsion springs. But that isn’t a guarantee it will last exactly that long in years — because your usage, door weight, environment (humidity, rust) and how well the door is balanced will all affect actual longevity. For some homes in our region with heavy doors and high use, the lifespan may be shorter.

If your door uses two torsion springs (which most double-car doors do) and one breaks, the other one has gone through essentially the same number of cycles and is usually very near its limit too. Even if it hasn’t snapped yet, it’s fatigued. Replacing only one spring means you’re leaving yourself another service call soon. It’s far more cost-effective and reliable to replace both springs when we’re already working on the system.

Because many homes here have heavier hurricane-rated doors and frequent use (garage as main entry, large family, opening often), springs often last anywhere from about 3 to 12 years, depending on cycles, door weight, and maintenance. If a spring breaks it’s a clear sign the material has reached its cycle limit. Our goal is to install properly rated springs and balance the door so it runs for as long as the materials allow.

Standard residential torsion springs are rated around the 10,000-cycle mark. High-cycle springs are built with thicker wire, more coils, or larger diameter to increase lifespan—some might be rated 20,000, 30,000 cycles or more. If you use your door very often, or have a heavy door, a high-cycle spring is a smart investment.

Because it’s a simple image that helps homeowners understand fatigue in a metal coil. Just as repeatedly bending a paper clip eventually causes it to snap, each garage-door cycle bends the torsion spring slightly. Over thousands of cycles, the metal fatigue builds up. By using that metaphor, we’re speaking plainly about what the mechanic sees on site — not just quoting numbers, but giving you a relatable explanation.

Yes — absolutely. A heavier door, larger panels, added insulation, or stronger lift hardware means the springs do more work with each cycle. If a door weighs more, the spring wears faster. Also, if the door isn’t balanced properly or the cables/drums are worn, that extra strain shortens spring life. That’s why we weigh the door, measure, and cut springs on site — so the spring is matched precisely to the door.

While it is technically possible, we don’t recommend it. If we only replace one spring, you’re leaving the second one near its failure point — and because the system is already open and we’re doing the labor, it makes much more sense to do the work once and be done. It’s a better value and results in fewer future service calls.

After proper spring replacement and balancing you’ll notice several subtle things: the door lifts with less effort (by hand or opener), it stays where you leave it (around waist height when tested), it moves smoothly and quietly, and the opener isn’t straining or binding. It won’t be dramatically flashy — but it will just work right. That steady, smooth operation is what we aim to deliver every time.